Zapatas Rimadoras

Pen-O-Trator®

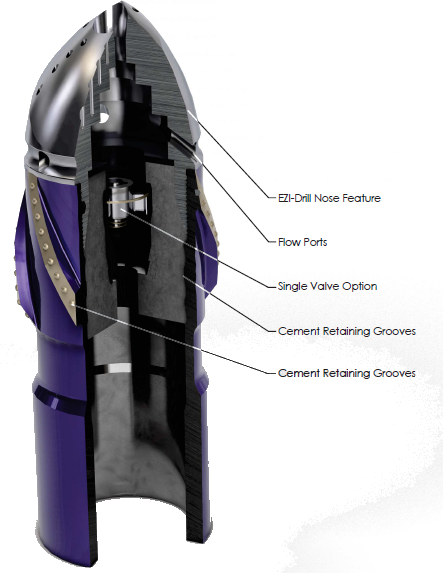

The Pen-O-Trator reamer shoe has been specifically designed to aid with the installation of any casing, liner or screen application where the operator has concerns over potential difficult wellbore conditions such as swelling shales, ledges and washed out areas within the wellbore.

Features:- Casing friendly tungsten carbide cutting structure

- Anti-aggressive left-hand blades minimize torque

- 360° cutting structure facilitates reaming past obstructions with or without rotation

- Wellbore seeking eccentric guide nose negotiates troublesome formations

- EZI-Drill® aluminum guide nose to aid drill-out without compromising nose strength

- Flow ports offering 360° flow area

- Slick body design helps reduce ECD

Options

- Standard 5,000 PSI & 10,000 PSI valves

- Single, double & auto-fill valve options

- Ball deflector / ball catcher options available

- All API and premium connections available

- All material casing grades available

The Pen-O-Trator reamer shoe has been specifically designed to aid with the installation of any casing, liner or screen application where the operator has concerns over potential difficult wellbore conditions such as swelling shales, ledges and washed out areas within the wellbore.

Features:

- Casing friendly tungsten carbide cutting structure

- Anti-aggressive left-hand blades minimize torque

- 360° cutting structure facilitates reaming past obstructions with or without rotation

- Wellbore seeking eccentric guide nose negotiates troublesome formations

- EZI-Drill® aluminum guide nose to aid drill-out without compromising nose strength

- Flow ports offering 360° flow area

- Slick body design helps reduce ECD

Options

- All API and premium connections available

- All casing grades and weight options

- Customized OD to suit client requirements

- Integral single or dual float valve

Ezi-Drill

The Ezi-Drill nose feature is designed to withstand high set-down weights when running the casing to T.D. during drill out, the aluminum will break into small chips to avoid ‘bird-nestingˇ of the bit to allow for a quick drill-out tim